A while ago (years) I bought a couple of 'corncob' light bulbs like this:

- one cool white and one warm white. COB hadn't arrived yet so the LEDs were all discrete components; 6 boards with 16 LEDs each plus another 8 on the end, total 104. The WW one wasn't very bright but apart from that they were OK.

Until, that is, the CW one began to flicker, then 52 of the LEDs went off - half of the end ones and three of the 6 boards. I stuck it on one side rather than throw it out, because there are a lot of LEDs which might be useful for something. Recently I dug it out and thought I might investigate the fault.

The end cap just pulled off - not glued, just located by pins - and I found that the cap was just holding everything in place. The end board came out followed by each of the six 16-LED boards, and finally a small PCB with power components. The power board was wired to the bayonet cap connector (240V AC) and delivered about 176V DC to the end board and one long board. It was arranged so that the DC was split two ways at the end pcb, each feeding four LEDs and then wired across to a side pcb. Three side pcbs were wired in series and the common return was on the last one. This gives two parallel strings of 52 LEDs wired in series, each fed by the 176V DC.

The whole of one string was off, so the fault was obviously either an open LED or a bad connection. I checked the voltage down the chain from the top until it went from 115V at one LED to almost zero at the next - obviously this was the bad LED. Using the diode test function on my DVM, I tested the LED and it was open both ways. But so was the next. and so was every other one on both strings. It seems that the junction voltage on these LEDs is more than the 2.8V which the meter uses for testing. Checks on other diodes proved that the meter was working fine.

I went around every connection in the lamp, reverting to my experience as a quality control engineer. I found that about 10 connections had already been reworked and a further two were dry - clearly the quality of soldering is questionable. Perhaps if the labour costs are cheap enough, it makes it financially viable to employ remedial QC workers even though the product is bad. After all, it only needs to work long enough to get into the end user's appliance for a few minutes. After my loving ministrations, the lamp was still faulty so I decided that the dead LED was probably the only remaining fault.

I didn't have any spare diodes of this type, so I had to improvise. With 176V across 52 diodes, that's only 3.4V each, so the extra voltage across each of the others when one is bridged is only 66mV or about 2%. Of course the higher voltage means more power dissipated in each one, so shortens the lifespan, but not significantly. Luckily they fail open-circuit; if they failed short-circuit there would be a runaway chain effect, hardly noticeably at first but culminating in total extinction and a bang. I could replace the LED with a suitable resistor or diode but that meant more calculations and anyway, I don't have many resistors in stock.

Having decided that it was worth a try, I just put a short circuit across the faulty one and switched on.

The string was still dead! And now the 115V dropped at the next LED. I was wondering if I was actually causing a runaway effect. But in fact, all it was was that both diodes had died together. I won't keep doing this of course, but I shorted out the second diode too, and everything worked again. It all went back together without problems (or glue) and I now have a fully working bulb again.

All this is a lot of trouble to go to for one light bulb, but I was curious about the construction and the fault. More recently, the advent of chip-on-board (COB) LEDs has improved the performance of LED lighting, although I don't suppose the build quality is necessarily any better. The lesson is probably the old one - that cheap products with no warranty are likely to be a bad investment in the long run. I've had many LED bulbs since this one (in fact, it's hard to find anything else these days) and so far they have been very satisfactory. Nowadays I can buy an LED bulb for little more than the incandescent ones used to cost, so it makes sense to buy from a well-known manufacturer. They have their brand reputation to protect.

Mending my way

The trials and errors of an unrepentant follower of lost causes in the world of non-functional human technology.

Friday, 5 October 2018

Wednesday, 18 May 2016

Not Quite Toast [Dell laptop]

OK, here's a fine tale. Believe it or not - this story, and the accompanying photos, are absolutely true and unaltered.

In another life, I was an I.T. Support engineer in an academic institution. Although it wasn't strictly part of the job, I would often undertake minor repairs to the staff kit, such as mending frayed power cables or fixing broken connectors. There are quite a few tales there too, but I digress.

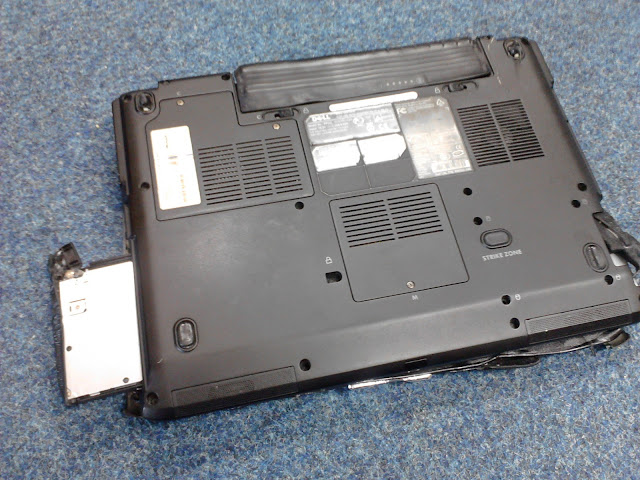

One day, a staff member came into the Helpdesk office bearing a carrier bag and a very sheepish expression. He had, he said, had an accident with his laptop, and it wasn't working, and did I think I could fix it? He opened the bag to reveal this mess:

After I stopped laughing (cruel, I know) I had to inform him that there was a chance that it might be beyond even my legendary abilities to resurrect this unfortunate item, and that he should bid a sorrowful farewell to his files and seek laptops new. This suggestion was accepted with a degree of rueful acknowledgement that in truth, he hadn't held out much hope anyway.

The full sequence of events was related. He had needed to go out of the house for a short time, and being conscious of the possibility of burglary he had looked around for a suitable place to conceal the laptop in his absence. As he was in the kitchen, the oven seemed to be a place that any thief would never look for a laptop, so in it went. Shortly after that, his wife came into the kitchen and proceeded to prepare the dinner, consisting in part of a nice apple crumble (you can see where this is heading). I suppose a black laptop does look a bit like a baking tray, but anyway for whatever reason she didn't realise the situation and switched on the oven to heat up while she mixed. After a while she noticed a distinctly un-crumbly smell and opened the oven....

Credit where it's due. Although the oven temperature clearly exceeded the melting point of most of the plastic components and turned them into a Dali-esque sculpture, this Dell has an alloy frame and top and bottom covers - these were surprisingly unaffected but the rest was, well, toast. The screen had melted and all the keys had evaporated from the keyboard, and everything was in a sorry state. I took the above photos just for the record because it's a sight you don't see often (although with Lithium Ion batteries becoming ubiquitous in cheap kit and charging not always sensibly controlled, we may see more incendiary incidents).

My colleague having gone off to throw himself under a handy train, I put the remains on a shelf and got on with something else.

Some time later I was poking at the pile of ash and I began to wonder what would happen if I connected a power supply to it. "Nothing" was the most I expected, although "lots of smoke and sparks" was also a possibility. Anyway, I went ahead and with the fire extinguisher close at hand, I connected the power unit and switched on. To my utter amazement, this is what I saw...

Not only did it not spark or catch fire, it actually booted as far as the command line and (rather superfluously) informed me that it couldn't see the hard drive, it couldn't understand the power supply parameters and it might not feel like charging the battery. It told me to strike the F1 key to continue but as you can see, there no longer was any F1 key. In fact if the key switches had not melted, it may have got further, but in the event I thought that it had already gone far beyond the call of duty, so I switched off.

The upshot of all this was that I chiselled out the hard drive and found that it was still operational, and I was able to recover my colleague's data for him. He was overjoyed and promised to tell Dell how impressed he was with the durability of their product, and he took away the bag of ashes for a decent burial.

Actually, it was a bit sad. This sturdy little machine was nobly doing its job and didn't ask, or deserve, to be baked to a crisp. I thought it was an effort worthy of high commendation that, with its last breath, it mustered enough life energy to let us know that it wasn't quite beaten. If it had not managed that, I wouldn't have attempted to remove the hard drive and try recovering the data, and all my colleague's work would have been lost.

Rest in peace, little champion.

In another life, I was an I.T. Support engineer in an academic institution. Although it wasn't strictly part of the job, I would often undertake minor repairs to the staff kit, such as mending frayed power cables or fixing broken connectors. There are quite a few tales there too, but I digress.

One day, a staff member came into the Helpdesk office bearing a carrier bag and a very sheepish expression. He had, he said, had an accident with his laptop, and it wasn't working, and did I think I could fix it? He opened the bag to reveal this mess:

After I stopped laughing (cruel, I know) I had to inform him that there was a chance that it might be beyond even my legendary abilities to resurrect this unfortunate item, and that he should bid a sorrowful farewell to his files and seek laptops new. This suggestion was accepted with a degree of rueful acknowledgement that in truth, he hadn't held out much hope anyway.

The full sequence of events was related. He had needed to go out of the house for a short time, and being conscious of the possibility of burglary he had looked around for a suitable place to conceal the laptop in his absence. As he was in the kitchen, the oven seemed to be a place that any thief would never look for a laptop, so in it went. Shortly after that, his wife came into the kitchen and proceeded to prepare the dinner, consisting in part of a nice apple crumble (you can see where this is heading). I suppose a black laptop does look a bit like a baking tray, but anyway for whatever reason she didn't realise the situation and switched on the oven to heat up while she mixed. After a while she noticed a distinctly un-crumbly smell and opened the oven....

Credit where it's due. Although the oven temperature clearly exceeded the melting point of most of the plastic components and turned them into a Dali-esque sculpture, this Dell has an alloy frame and top and bottom covers - these were surprisingly unaffected but the rest was, well, toast. The screen had melted and all the keys had evaporated from the keyboard, and everything was in a sorry state. I took the above photos just for the record because it's a sight you don't see often (although with Lithium Ion batteries becoming ubiquitous in cheap kit and charging not always sensibly controlled, we may see more incendiary incidents).

My colleague having gone off to throw himself under a handy train, I put the remains on a shelf and got on with something else.

Some time later I was poking at the pile of ash and I began to wonder what would happen if I connected a power supply to it. "Nothing" was the most I expected, although "lots of smoke and sparks" was also a possibility. Anyway, I went ahead and with the fire extinguisher close at hand, I connected the power unit and switched on. To my utter amazement, this is what I saw...

| |

| Phoenix or what? Way to go, Dell! |

The upshot of all this was that I chiselled out the hard drive and found that it was still operational, and I was able to recover my colleague's data for him. He was overjoyed and promised to tell Dell how impressed he was with the durability of their product, and he took away the bag of ashes for a decent burial.

Actually, it was a bit sad. This sturdy little machine was nobly doing its job and didn't ask, or deserve, to be baked to a crisp. I thought it was an effort worthy of high commendation that, with its last breath, it mustered enough life energy to let us know that it wasn't quite beaten. If it had not managed that, I wouldn't have attempted to remove the hard drive and try recovering the data, and all my colleague's work would have been lost.

Rest in peace, little champion.

Thursday, 5 May 2016

Who's bin naughty then? [Brabantia]

I always wanted one of those lovely Brabantia waste bins with the soft-touch latching lid. After trying the pedal, swing-top, lift-top, no-top and goodness knows how many other types, the idea of just touching the lid for it to open smoothly by itself and latching it shut with a gentle push-click was heaven. Also, they come in stainless steel and have a removable inner bin. They were always well out of my budget range, but I was lucky to find two at once - one 40 litre one for the kitchen, with a flat back to save space, and a smaller 35 litre cylindrical one for the bathroom, at a very reasonable price second-hand on eBay.

All went well for a few years. The main weakness with these is the peg onto which the spring latch grips, which can break if the lid is slammed carelessly. The mating spring catch is also consumable but is available as a spare part; on the early bins the peg is moulded in one piece with the whole lid frame, which is in turn hot-welded to the stainless steel outer. Thus, a broken peg means a new lid assembly which is a significant proportion of the cost of a new bin. These days I think that the peg is made separately and in any case there are third-party suppliers offering replacements in clip form, which will also fit the old style lid. However, as befits this mad household, my family were unwilling to break the bin in the conventional fashion. We waited until something was jammed over the peg and then tried to close the lid - when it wouldn't close, it was forced until it did, in the process twisting the lid and breaking the hinge at one end. The lid is supported by quite a strong spring acting on the hinge axis, The hinge can't be dismantled without removing the lid frame from the steel, which means breaking off all the moulded weld points and re-fixing the frame after repair with another method. So, I was faced with either buying a new lid assembly or repairing the existing hinge in situ against the spring pressure.

The form of the lid is like a plastic plate with the back edge rolled into a half-tube, inside which is the hinge pin (full-length axle joining both sides). The plastic had cracked so that the plate was separated from the remaining part of the half-tube attached to the spring.

Firstly I allowed the lid to open fully so that the spring was in its least stressed position. This allowed the two broken parts to be aligned and glued, but the joint was not nearly strong enough to cope with the spring force when the lid was being closed; so I clamped the joint in position and used epoxy glue (Araldite) both to join the pieces and to fix a short steel pin over the break at each end (along the edge of the plate/tube). Shortened panel pins were ideal for this, strengthening the joint without projecting on either side of the joint - if they did it would interfere with either the hinge action or the next phase of repair.

I looked for a length of steel or plastic pipe of the same diameter as the 'rolled half-tube' section. As it happened I had just replaced a shower curtain rail because the plastic coating had disintegrated; under it was a plain mild steel tube (a bit rusty) of 1" diameter. However, this was a little small for what I had in mind, which was to cut and shape a section to fit over the plastic rolled half-tube. When glued in place all along the length, it would sheath and essentially replace the function of the plastic half-tube and support the broken part completely. As it was all I could find, I cut the steel tube to length, de-rusted it and used emery paper to give it a brushed appearance like the bin surface, then cut it down its length in two places to give a part-cylinder. Then I needed to gradually open up the cylinder to a larger radius, until I could clip it firmly over the plastic tube. I then coated the whole inside of it with polyurethane glue (Gorilla Glue), wiped the plastic tube with water to speed the cure, and clipped it into place over the plastic tube. I clamped it in various places and left it overnight to cure, and when ready I tested the action with complete success.

The only remaining job was to give the bare brushed steel a coat of polyurethane laquer to protect it from the horrid bin contents, and to make it look like part of the original equipment.

|

| The lid in question |

All went well for a few years. The main weakness with these is the peg onto which the spring latch grips, which can break if the lid is slammed carelessly. The mating spring catch is also consumable but is available as a spare part; on the early bins the peg is moulded in one piece with the whole lid frame, which is in turn hot-welded to the stainless steel outer. Thus, a broken peg means a new lid assembly which is a significant proportion of the cost of a new bin. These days I think that the peg is made separately and in any case there are third-party suppliers offering replacements in clip form, which will also fit the old style lid. However, as befits this mad household, my family were unwilling to break the bin in the conventional fashion. We waited until something was jammed over the peg and then tried to close the lid - when it wouldn't close, it was forced until it did, in the process twisting the lid and breaking the hinge at one end. The lid is supported by quite a strong spring acting on the hinge axis, The hinge can't be dismantled without removing the lid frame from the steel, which means breaking off all the moulded weld points and re-fixing the frame after repair with another method. So, I was faced with either buying a new lid assembly or repairing the existing hinge in situ against the spring pressure.

The form of the lid is like a plastic plate with the back edge rolled into a half-tube, inside which is the hinge pin (full-length axle joining both sides). The plastic had cracked so that the plate was separated from the remaining part of the half-tube attached to the spring.

Firstly I allowed the lid to open fully so that the spring was in its least stressed position. This allowed the two broken parts to be aligned and glued, but the joint was not nearly strong enough to cope with the spring force when the lid was being closed; so I clamped the joint in position and used epoxy glue (Araldite) both to join the pieces and to fix a short steel pin over the break at each end (along the edge of the plate/tube). Shortened panel pins were ideal for this, strengthening the joint without projecting on either side of the joint - if they did it would interfere with either the hinge action or the next phase of repair.

I looked for a length of steel or plastic pipe of the same diameter as the 'rolled half-tube' section. As it happened I had just replaced a shower curtain rail because the plastic coating had disintegrated; under it was a plain mild steel tube (a bit rusty) of 1" diameter. However, this was a little small for what I had in mind, which was to cut and shape a section to fit over the plastic rolled half-tube. When glued in place all along the length, it would sheath and essentially replace the function of the plastic half-tube and support the broken part completely. As it was all I could find, I cut the steel tube to length, de-rusted it and used emery paper to give it a brushed appearance like the bin surface, then cut it down its length in two places to give a part-cylinder. Then I needed to gradually open up the cylinder to a larger radius, until I could clip it firmly over the plastic tube. I then coated the whole inside of it with polyurethane glue (Gorilla Glue), wiped the plastic tube with water to speed the cure, and clipped it into place over the plastic tube. I clamped it in various places and left it overnight to cure, and when ready I tested the action with complete success.

The only remaining job was to give the bare brushed steel a coat of polyurethane laquer to protect it from the horrid bin contents, and to make it look like part of the original equipment.

|

| It's bin mended! |

Wednesday, 4 May 2016

Return of the Were-Rabbit* [Dutch Dwarf Lop]

Rabbits are very cute, I suppose, although skinny - when I handle a rabbit it always reminds me of a velvet pouch full of bones - but they have ferociously efficient teeth. I haven't been fully bitten, only nipped, but having seen what they can do to thin aluminium sheet and copper wiring, I don't want to have those chisel teeth anywhere near my flesh.

My daughters have for years had two pet rabbits at any one time (in rotation - one of the first pair had to be replaced as too aggressive, another disappeared overnight probably to sustain some nocturnal predator, and two died) and they had occasionally been allowed in the house. She Who Must Be Obeyed likes the idea of "house rabbits". I let this happen assuming that at least the poop would be cleaned up - not always the case, unfortunately - but I stopped it after discovering that the new sofa was ripped and the Christmas lights and my computer power supply lead had both been sliced into several parts by rabbity dentition. The power was on at the time, yet the perpetrator was unharmed. Maybe their teeth are made of a ceramic non-conductor.

Anyway, after an interval long enough for me to forget the above incident, Bagel - one of the current pair - was found demonstrating rigor mortis one day. The pair were well bonded and it was clear that the survivor Thumper would pine after his departed friend during the night, and the weather was cold with no cosy partner to snuggle up to. So my elder daughter decided that she would take him into her bedroom overnight until either a new partner was found or he was re-homed. I thought little about this as she is now old enough to deal with things like animal care. Or so I thought.

After a couple of weeks, one day when I eventually surfaced from my bed I was informed that there had been a power cut for several hours. On investigating I discovered that the 'power cut' was restricted to our own house, and no-one had thought to check the fusebox. In fact, the main safety RCD had tripped and resetting it restored the power immediately. A few days later it happened again, this time taking out the RCD and the Miniature Circuit Breaker protecting the mains power outlets. Resetting both restored power again, and I checked every item connected to the mains circuit downstairs but could find no problem. The next time it occurred I found that on resetting the trips they immediately dropped out again (but intermittently) and I spent the next two hours carefully inspecting every outlet in the house and its associated loads.

The fault, when finally revealed, was horrifying. In my daughter's bedroom, she had a four-way power extension plugged into the wall outlet and had routed the cable under her desk, round the back of her high bunk bed and up to her bedside cupboard to supply lights and phone charger. She had created a curtained-off "den" under her bed into which she used to retreat to read in privacy, and she had lined the den with spare bedding and pillows and a bookcase. When I looked into the den I discovered that she had been using it as a rabbit hutch for Thumper , and she had not been cleaning up the rabbit poop and uneaten food. The bedding and carpet were soaked with urine. There were shredded books in evidence, and on lifting the bedding I found that the extension cable had been extensively stripped - all three wires were bared and had been sparking together. How a fire was avoided I shall never know. Even though the short circuits had tripped the MCB, the sparking could have caused the bedding/paper to smoulder and burn undetected.

The damaged wiring was removed and repaired but I kept it back until the room had been fully cleaned by my daughter and inspected for approval by parents. Needless to say, the rabbit was banished back to its usual accommodation and is now awaiting return to Rabbits 'r' Us to await a new owner.

This is posted as a cautionary tale, because we were lucky to escape more serious consequences (as was the rabbit). I have found that rabbits are able to bite through most materials and ours stripped out the carefully-fitted insulation in their hut and did considerable damage to the woodwork. They also kept digging tunnels under the fences, and undermined the foundation of our garden shed twice. Rabbit poop is relatively innocuous but is unpleasant when it is allowed to build up to six inches deep. During their stay ours have also seriously damaged a new sofa and several cushions, pillows and towels - plus the various electrical and other items. To add a final sting, when we contacted Rabbits 'r' Us to arrange his re-homing, they insisted on his having his immunisation renewed at our expense (and expensive it certainly was). All in all - I do generally love animals and the rabbits were cute, but I shall be heartily glad to see the back of them. We had a lovely cat but she had to go as my wife is allergic to the fur. We still support a dog, two goldfish and a horse; and my wife wants to keep chickens again...

[Names have been changed to protect the guilty]

* With grateful acknowledgement to ©Aardman

My daughters have for years had two pet rabbits at any one time (in rotation - one of the first pair had to be replaced as too aggressive, another disappeared overnight probably to sustain some nocturnal predator, and two died) and they had occasionally been allowed in the house. She Who Must Be Obeyed likes the idea of "house rabbits". I let this happen assuming that at least the poop would be cleaned up - not always the case, unfortunately - but I stopped it after discovering that the new sofa was ripped and the Christmas lights and my computer power supply lead had both been sliced into several parts by rabbity dentition. The power was on at the time, yet the perpetrator was unharmed. Maybe their teeth are made of a ceramic non-conductor.

|

| Our first pair |

Anyway, after an interval long enough for me to forget the above incident, Bagel - one of the current pair - was found demonstrating rigor mortis one day. The pair were well bonded and it was clear that the survivor Thumper would pine after his departed friend during the night, and the weather was cold with no cosy partner to snuggle up to. So my elder daughter decided that she would take him into her bedroom overnight until either a new partner was found or he was re-homed. I thought little about this as she is now old enough to deal with things like animal care. Or so I thought.

After a couple of weeks, one day when I eventually surfaced from my bed I was informed that there had been a power cut for several hours. On investigating I discovered that the 'power cut' was restricted to our own house, and no-one had thought to check the fusebox. In fact, the main safety RCD had tripped and resetting it restored the power immediately. A few days later it happened again, this time taking out the RCD and the Miniature Circuit Breaker protecting the mains power outlets. Resetting both restored power again, and I checked every item connected to the mains circuit downstairs but could find no problem. The next time it occurred I found that on resetting the trips they immediately dropped out again (but intermittently) and I spent the next two hours carefully inspecting every outlet in the house and its associated loads.

The fault, when finally revealed, was horrifying. In my daughter's bedroom, she had a four-way power extension plugged into the wall outlet and had routed the cable under her desk, round the back of her high bunk bed and up to her bedside cupboard to supply lights and phone charger. She had created a curtained-off "den" under her bed into which she used to retreat to read in privacy, and she had lined the den with spare bedding and pillows and a bookcase. When I looked into the den I discovered that she had been using it as a rabbit hutch for Thumper , and she had not been cleaning up the rabbit poop and uneaten food. The bedding and carpet were soaked with urine. There were shredded books in evidence, and on lifting the bedding I found that the extension cable had been extensively stripped - all three wires were bared and had been sparking together. How a fire was avoided I shall never know. Even though the short circuits had tripped the MCB, the sparking could have caused the bedding/paper to smoulder and burn undetected.

|

| Rabbit food? |

This is posted as a cautionary tale, because we were lucky to escape more serious consequences (as was the rabbit). I have found that rabbits are able to bite through most materials and ours stripped out the carefully-fitted insulation in their hut and did considerable damage to the woodwork. They also kept digging tunnels under the fences, and undermined the foundation of our garden shed twice. Rabbit poop is relatively innocuous but is unpleasant when it is allowed to build up to six inches deep. During their stay ours have also seriously damaged a new sofa and several cushions, pillows and towels - plus the various electrical and other items. To add a final sting, when we contacted Rabbits 'r' Us to arrange his re-homing, they insisted on his having his immunisation renewed at our expense (and expensive it certainly was). All in all - I do generally love animals and the rabbits were cute, but I shall be heartily glad to see the back of them. We had a lovely cat but she had to go as my wife is allergic to the fur. We still support a dog, two goldfish and a horse; and my wife wants to keep chickens again...

[Names have been changed to protect the guilty]

* With grateful acknowledgement to ©Aardman

Sunday, 22 February 2015

Re-launch tips [Shelves and roller blinds]

After a VERY long gap, caused by all sorts of personal things which no-one is interested in (except maybe a psychiatrist or a divorce court), I keep meaning to get back into the habit of documenting this stuff. I haven't stopped mending but I haven't felt like writing it down. In fact I haven't felt like much at all really; the Black Dog is at my heels. I decided to begin a New Phase of life.

So, to start off the New Phase, here's a couple of tips:

Tip 1- Roller Blinds.

These (the manual kind) have a habit of needing constant adjustment. The pulley at the end, with the string round it, is attached to the roller, and when insensitive clods jerk the string the knob on the other end of the string rises until the knob bangs against the bracket. The friction bond between the string and pulley slips a little and the blind's position relative to the string has changed. The net result of this is that with successive bangs, the roller blind goes up and up until it starts to jam at the top or doesn't reach the bottom any more when the string is pulled down to its full extent.

The official remedy is to unhook the roller blind, turn it over to unwind a turn of fabric and re-seat it in the brackets, which makes it one roller-circumference longer with the string position unchanged. What a hassle this becomes when you have a house full of clods.

My solution is to thread a long compression spring (such as a ball-point pen spring) onto each end of the string before the knobs are tied in place. Then (with everything adjusted to taste) the meteoric rise (or fall) of the blind is brought to a dignified stop, it doesn't slip its string and the adjustment remains correct. Clods can pull as hard as they want whilst civilised persons can choose their optimum blind parking position by feeling the tension. Simples.

>>UPDATE: It seems that the insensitive clods are more persistent than I had assumed, as the blind is still being shifted (but not as much). Perhaps it's time to change to a different kind of privacy arrangement.

Tip 2 - Adjustable Shelves.

When using the slotted-rail shelf supports of the Spur type (<ahem>, other shelf support brands are available...) you are expected to fix the shelves by screws through the shelf brackets. If you fix them as far back as they will go, there is a half-inch gap between shelf and wall, and stuff keeps falling down. If you cunningly notch the shelf to clear the vertical supports so it fits against the wall this won't happen. BUT in either case you sacrifice the convenience of adjustability, because in order to move the shelf you have to tip it up at 45 degrees to allow the brackets to come free of the vertical supports - which you can't do with the shelf screwed down and fixed against the supports.

My solution is to mark and notch the shelf as above, to fit round the supports. Then the shelf is put to the saw and the rearmost 30mm or so of the shelf (including the notches) is cut off. The two parts are then replaced on the brackets and fitted snugly up against the wall - closing the saw kerf - and the front part ONLY of the shelf is screwed to its brackets. You then have a complete and gap-free shelf, but if you need to move it you just lift out the back 30mm strip which leaves a gap big enough to allow the shelf (with brackets) to be tilted and removed from the supports without unscrewing it. It can then be relocated at another position and the filler strip dropped back in to restore the neat installation.

So, to start off the New Phase, here's a couple of tips:

Tip 1- Roller Blinds.

These (the manual kind) have a habit of needing constant adjustment. The pulley at the end, with the string round it, is attached to the roller, and when insensitive clods jerk the string the knob on the other end of the string rises until the knob bangs against the bracket. The friction bond between the string and pulley slips a little and the blind's position relative to the string has changed. The net result of this is that with successive bangs, the roller blind goes up and up until it starts to jam at the top or doesn't reach the bottom any more when the string is pulled down to its full extent.

The official remedy is to unhook the roller blind, turn it over to unwind a turn of fabric and re-seat it in the brackets, which makes it one roller-circumference longer with the string position unchanged. What a hassle this becomes when you have a house full of clods.

My solution is to thread a long compression spring (such as a ball-point pen spring) onto each end of the string before the knobs are tied in place. Then (with everything adjusted to taste) the meteoric rise (or fall) of the blind is brought to a dignified stop, it doesn't slip its string and the adjustment remains correct. Clods can pull as hard as they want whilst civilised persons can choose their optimum blind parking position by feeling the tension. Simples.

>>UPDATE: It seems that the insensitive clods are more persistent than I had assumed, as the blind is still being shifted (but not as much). Perhaps it's time to change to a different kind of privacy arrangement.

Tip 2 - Adjustable Shelves.

When using the slotted-rail shelf supports of the Spur type (<ahem>, other shelf support brands are available...) you are expected to fix the shelves by screws through the shelf brackets. If you fix them as far back as they will go, there is a half-inch gap between shelf and wall, and stuff keeps falling down. If you cunningly notch the shelf to clear the vertical supports so it fits against the wall this won't happen. BUT in either case you sacrifice the convenience of adjustability, because in order to move the shelf you have to tip it up at 45 degrees to allow the brackets to come free of the vertical supports - which you can't do with the shelf screwed down and fixed against the supports.

My solution is to mark and notch the shelf as above, to fit round the supports. Then the shelf is put to the saw and the rearmost 30mm or so of the shelf (including the notches) is cut off. The two parts are then replaced on the brackets and fitted snugly up against the wall - closing the saw kerf - and the front part ONLY of the shelf is screwed to its brackets. You then have a complete and gap-free shelf, but if you need to move it you just lift out the back 30mm strip which leaves a gap big enough to allow the shelf (with brackets) to be tilted and removed from the supports without unscrewing it. It can then be relocated at another position and the filler strip dropped back in to restore the neat installation.

Sunday, 12 May 2013

Reinforcing the lesson [Chinese tools]

Not much activity on the mending front recently. However, as if to hammer home the point of my previous post, a new shipment of Chinese stuff has needed to be returned. CPC had several things in their special offers and Clearance lists, so I purchased two PIR alarms - exactly the same model that I purchased on Police recommendation some thirteen years ago, but now only £8 instead of £33. Also there was a Crimping Tool Kit which had metric bolt cutting slots for 2mm to 5mm screws, and my old one is only suited for BA threads. With a selection of crimp connectors and a carrying case, the kit was less than £3.50. I also needed some AA batteries (for the alarms etc) and they were offering a 32-pack of Philips ones for around £7.

The stuff came promptly but was a disappointment. One of the PIR alarms was fine but the other proved to be missing a connector strip in the battery compartment, so could not be used at all. So much for the QC inspection sticker...! Of the 32 batteries, five were leaking and partially discharged and as it was a sealed batch, I didn't trust the others - especially as they were going into the alarms for perhaps a year. The expiry date on each battery was October 2017. The rather weak crimp tool was completely Imperial and had nothing metric about it - all cutting points had American wire gauge designations and the AF threads in the bolt cutters would not accept metric screws. The crimp connectors seem flimsy and looked as though the PVC insulation would split when crimped, and finally both latches were broken off the case so it couldn't be closed.

Result: it all has to go back and we start again. I will accept a replacement PIR as they are usually good; the Crimp Kit was described as "metric" but probably isn't even available as such, and I will definitely be going for a different brand of batteries. My experience of Duracell is that even when discharged they don't leak (even though they too may be Chinese sourced, who knows). Maybe in time I will learn that a bargain is not a bargain unless it's a good product for a lower price than usual, and that bad products sold for their actual value are not a good investment.

================

UPDATE 11 July 2014

================

Given two apparently working PIR alarms, I installed them with confidence. After a few months, one has proved to be hard to use as the button action needs a really hard press, and the other has simply decided to sound off whenever it feels the need - even locked in a shed with no movement (and no insects or air currents etc). I should have known...serves me right.

===================================

When I was helping my father-in-law repair his garden shed, I leaned on the arm of his garden bench which promptly snapped off. The wood was rotten around the mounting bolt. I was intending to cut it out and let in a new patch of hardwood, but decided it was easier to replace the whole part with a new one in good pine. Having made a new bracket with the requisite holes, counterbores and such I soaked it all in wood preserver and gave it two coats of fence paint. It should now outlast the rest of the bench, and probably both my father-in-law and me too.

The stuff came promptly but was a disappointment. One of the PIR alarms was fine but the other proved to be missing a connector strip in the battery compartment, so could not be used at all. So much for the QC inspection sticker...! Of the 32 batteries, five were leaking and partially discharged and as it was a sealed batch, I didn't trust the others - especially as they were going into the alarms for perhaps a year. The expiry date on each battery was October 2017. The rather weak crimp tool was completely Imperial and had nothing metric about it - all cutting points had American wire gauge designations and the AF threads in the bolt cutters would not accept metric screws. The crimp connectors seem flimsy and looked as though the PVC insulation would split when crimped, and finally both latches were broken off the case so it couldn't be closed.

Result: it all has to go back and we start again. I will accept a replacement PIR as they are usually good; the Crimp Kit was described as "metric" but probably isn't even available as such, and I will definitely be going for a different brand of batteries. My experience of Duracell is that even when discharged they don't leak (even though they too may be Chinese sourced, who knows). Maybe in time I will learn that a bargain is not a bargain unless it's a good product for a lower price than usual, and that bad products sold for their actual value are not a good investment.

================

UPDATE 11 July 2014

================

Given two apparently working PIR alarms, I installed them with confidence. After a few months, one has proved to be hard to use as the button action needs a really hard press, and the other has simply decided to sound off whenever it feels the need - even locked in a shed with no movement (and no insects or air currents etc). I should have known...serves me right.

===================================

When I was helping my father-in-law repair his garden shed, I leaned on the arm of his garden bench which promptly snapped off. The wood was rotten around the mounting bolt. I was intending to cut it out and let in a new patch of hardwood, but decided it was easier to replace the whole part with a new one in good pine. Having made a new bracket with the requisite holes, counterbores and such I soaked it all in wood preserver and gave it two coats of fence paint. It should now outlast the rest of the bench, and probably both my father-in-law and me too.

Tuesday, 16 April 2013

Chinese quality tools [Rotacraft and Proxxon accessories]

I own a Proxxon FBS 240/E multi-tool, similar to the Dremel, which I find very useful. I'm pretty happy with the quality and I've got a number of other Proxxon products as a result. In general they are well made, which is as well because they aren't particularly cheap. I've had to do a little fettling to the metalwork but nothing serious. They are supposed to be made in Germany and until the other day I had not seen any obvious clones, which is usually a sure indication that badge-engineering of far-eastern products is taking place. My tool holder uses a suction base with a spherical mount, and this particular model is no longer sold by Proxxon - they changed to a conventional clamp base - but the FMZ table vice is available with the clamp and also still with the suction base as the FMS 75. I was therefore surprised to see a very similar item being sold by Draper. I don't know whether this is the same thing from a common supplier, or a copy from China or elsewhere. It looks the same though, and is in the same price range, so it may be German. The fettling on my tool holder, by the way, was that I had to file away a casting seam and the paint from the ball to allow it rotate smoothly. The current production has the ball properly cleaned up with no paint and a smooth spherical surface. On the whole, at this price and quality I think these are European, because you can get something similar for only a few pounds - and which really IS rubbish.

The lesson I have learned finally, after repeated bad experience, is that it simply is not worth buying cheap tools. They are cheap for a reason, and if a tool won't match up to its job then it is worse than useless (because it may do damage). Many years ago I got a cheap set of Allen keys - early Chinese imports - and the first time I used them they simply twisted like sugar candy canes. A good Allen key will break before it bends, and even then not until it has been stressed far beyond the usual requirements. Cheap screwdrivers or bits will twist and damage the screw head. My first sharpening stone ('oil stone') wore away like chalk and when I added oil, it dissolved. I recently purchased a 1/2" twist drill bit from Machine Mart and had to return it due to the visible bend in it; the replacement was also slightly bent but not sufficiently to render it unusable for my application. In future I will only buy industrial quality drills from English, German or American manufacturers. Properly used, they will outlast my lifetime.

Anyway - back to the multi-tool - although the supplied accessories were OK there was only a limited selection, so when I saw a Rotacraft 400-piece accessory kit on offer I decided to have one, so that I would have pretty well everything I might need in a hurry. I should have known - the same kit is available under the Duratool brand, but missing lots of cutting discs and sold as a 150-piece kit. The swanky display box broke within minutes. This is a dead cert for a Chinese import, and unfortunately I paid the penalty. The first time I needed a micro drill I was drilling polypropylene plastic - not exactly a taxing job - and the drill simply refused to penetrate. The next size up was not much better but did drill a hole of sorts. I had a close look at the drill tip and it was off centre and had a flat across the tip - it wouldn't even make a good nail as it isn't hard enough or sharp enough. I also noted that one of the grinding wheels was incomplete and the rest were anything but round. I suppose you could dress them to be concentric, but I fear that they probably won't be much use even then.

|

| The Proxxon FMS 75 vice... |

|

| ...and Snap! But I quite like the blue. |

The lesson I have learned finally, after repeated bad experience, is that it simply is not worth buying cheap tools. They are cheap for a reason, and if a tool won't match up to its job then it is worse than useless (because it may do damage). Many years ago I got a cheap set of Allen keys - early Chinese imports - and the first time I used them they simply twisted like sugar candy canes. A good Allen key will break before it bends, and even then not until it has been stressed far beyond the usual requirements. Cheap screwdrivers or bits will twist and damage the screw head. My first sharpening stone ('oil stone') wore away like chalk and when I added oil, it dissolved. I recently purchased a 1/2" twist drill bit from Machine Mart and had to return it due to the visible bend in it; the replacement was also slightly bent but not sufficiently to render it unusable for my application. In future I will only buy industrial quality drills from English, German or American manufacturers. Properly used, they will outlast my lifetime.

Anyway - back to the multi-tool - although the supplied accessories were OK there was only a limited selection, so when I saw a Rotacraft 400-piece accessory kit on offer I decided to have one, so that I would have pretty well everything I might need in a hurry. I should have known - the same kit is available under the Duratool brand, but missing lots of cutting discs and sold as a 150-piece kit. The swanky display box broke within minutes. This is a dead cert for a Chinese import, and unfortunately I paid the penalty. The first time I needed a micro drill I was drilling polypropylene plastic - not exactly a taxing job - and the drill simply refused to penetrate. The next size up was not much better but did drill a hole of sorts. I had a close look at the drill tip and it was off centre and had a flat across the tip - it wouldn't even make a good nail as it isn't hard enough or sharp enough. I also noted that one of the grinding wheels was incomplete and the rest were anything but round. I suppose you could dress them to be concentric, but I fear that they probably won't be much use even then.

|

| Cunningly designed to not drill holes... |

|

| ...or be any use at all. |

The fact is, that if a tool is sourced from China or elsewhere and is cheap, it probably is worth only its price. The Chinese can certainly produce the highest quality goods - they couldn't get a space rocket to the moon using rubbish tools - but so can we, and they cost good money. Given that everything we buy from foreign suppliers has to be paid for by selling something else to them or by borrowing money (probably from them), I would prefer to buy quality tools whose price will go back into the European economy whenever I can afford it. This means doing lot more research into the actual source of the things I buy, and whether they are fairly priced or overpriced, but in the end it is worth it.

Subscribe to:

Comments (Atom)